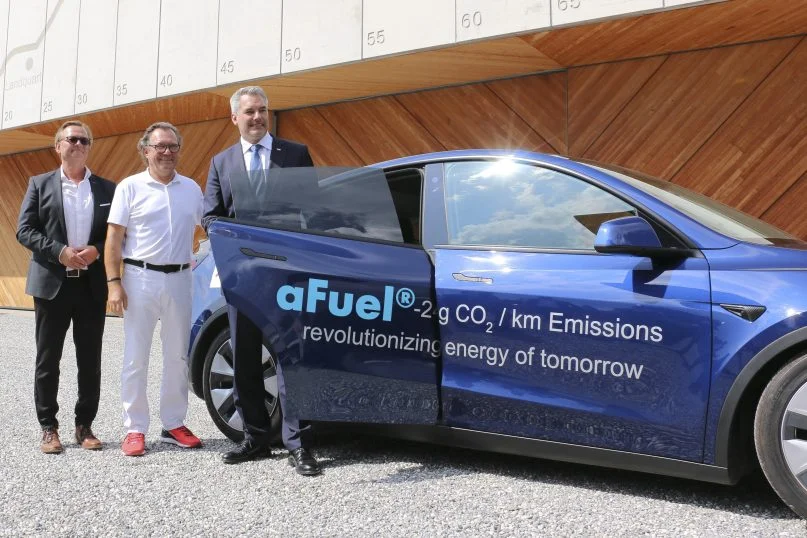

The much-praised “technology openness” becomes tangible here: The team from the Austrian-German Obrist Group is bringing a new dimension of sustainable automotive mobility to the road with HyperHybrid® Powertrain. And more than that: In Lindau, they are developing the world’s first CO2-negative energy carrier. It could soon ensure that less CO2 is emitted during combustion while driving than is removed from the air during the production of aMethanol.

In Lustenau, the Austrian location of the Obrist Group, they don’t waste time. They produce a modern hybrid vehicle prototype as follows: They take a Tesla and first remove the batteries. Then, the vehicle receives a new, much smaller battery. It is powered by a two-cylinder internal combustion engine. The engine is fueled with aMethanol (atmospheric Methanol – obtained from the air by removing water and CO2). Frank Obrist, CEO of the Obrist Group, is convinced of his solution: “lightweight, affordable, resource-efficient, and therefore affordable for ordinary citizens worldwide.”

Obrist describes mainstream hybrid cars as “run-of-the-mill vehicles,” powered by a highly developed four-cylinder engine, with “a bit of electrification” added. “We come from the other, the electric side, and make it smarter and more efficient.” Because an electric car has many advantages for Obrist. It runs emission-free in urban areas, has smooth acceleration without a gearbox, and brake energy is recaptured through recuperation, recharging the battery instead of heating up brake discs. The prototype vehicle in Lustenau is called HyperHybrid or Electric Vehicle 2.0.

Zero Vibration Generator

Obrist’s 45 kW two-cylinder engine is an in-house development. It doesn’t need to rev high like a conventional car engine; instead, it operates, if at all, in the optimal RPM range. As a result, it is more efficient and designed for smooth operation. “What one cylinder does wrong counterclockwise, the other does wrong clockwise.” This technique eliminates any vibrations. Additionally, it is enclosed and therefore barely audible. The task of the “Zero Vibration Generator” is to generate power for the electric motor, charge the battery, and, if necessary, power the air conditioning.

Because it primarily buffers, it is relatively small with a capacity of 17.3 kilowatt-hours. The original Tesla batteries, which have multiple times the capacity, exist in a different world. In Obrist’s overall system, the battery exchange is the key. “That reduces costs and saves the most resources.” Consequently, the newly built Model Y is significantly lighter than the original Tesla. According to Obrist, in mixed driving conditions (WLTP), the vehicle can get by with just two liters of aMethanol. The CEO claims a range of 1,000 kilometers for the HyperHybrid prototype vehicle. “That means I can drive from Lindau to Hamburg without refueling.”

E-Fuels from the Desert

Currently, the prototypes are fueled with regular gasoline, Mixed Fuel (80% gasoline, 15% aMethanol, and 5% aEthanol), or pure methanol. In terms of fuel, Vorarlberg is thinking quite innovatively. The goal is nothing less than to lead global mobility into a CO2-neutral future.

To achieve this, Obrist relies on a scientific concept called “The Modern Forest.” It’s a factory for aMethanol based on the principle of “Everything in one place.” This includes the production of electricity, hydrogen, and methanol – in that order. In the sunbelt regions of the world, energy is available at extremely low prices. Obrist refers to the Al Dahfra photovoltaic plant in Abu Dhabi, with a price of 1.14 cents per kilowatt-hour. The CEO is fascinated by the innovation and price drop that photovoltaic technology has undergone in recent decades: from about 50 cents per kilowatt-hour down to the mentioned price of less than one cent.

In the further production steps of these facilities in the sunbelt regions of the world, Obrist relies on electrolysis and the extraction of CO2 from the atmosphere. Direct Air Capture is, for Frank Obrist, the ultimate solution. The end product is always methanol, which is supposed to be transported through pipelines and tanker ships. Obrist explicitly refers to Siemens Energy’s Haru Oni project in South Chile. “This package differs primarily in obtaining the cheapest electricity through photovoltaics, as well as the much cheaper and patented DAC process compared to the process presented by Siemens Energy and Porsche. They generate electricity through wind and ultimately provide a gasoline substitute. In contrast, we want to build a global energy carrier. And that is E-Methanol.”

The solution already exists

As pure production costs for a ton of E-Methanol, Obrist states $240 to $280 per ton. This is roughly in line with the current price level of fossil-produced methanol. “If this makes economic sense, then even oil-exporting countries, such as Saudi Arabia, located in the world’s sunbelt, will develop a high degree of interest. Provided that it results in a positive business case.” According to Obrist, there are already talks with partners in the Arabian region.

Unlike Siemens Energy, whose project is nearing implementation, the entire “The Modern Forest” facility, except for the DAC process, only exists on paper so far. Of course, Frank Obrist knows that a medium-sized company alone cannot revolutionize the global energy system. “But this is the package for now. We have it in the drawer. We may not have billions right now, but at least we have the solution in hand.”

In the meantime, Frank Obrist has written a letter to American entrepreneur Elon Musk and explained his ideas to him. Musk also wants to contribute to solving the climate problem. Like Frank Obrist, he sees himself as having a “duty to deliver” in solving this global issue.

Next Steps

The Obrist Group comes from the automotive supply industry. They work, for example, with Audi, BMW, and Daimler. They developed the first environmentally friendly air conditioning system with the refrigerant R744 for the Mercedes S-Class.

Now, Obrist is betting on the HyperHybrid. “We have built 10 prototype vehicles this year alone.” And they are all based on the Tesla Model Y. Frank Obrist sees several advantages in this vehicle. It has an especially aerodynamic shape and a good length. “And we are combining that for the first time in history with aMethanol, enabling a continuous look into the future.” According to Frank Obrist, the vehicle and the visionary fuel go hand in hand. In Vorarlberg, they are approaching these questions in a practical way: How does such a car drive? What emissions does it produce? Why is it carbon-neutral? “We want to convey these things to politics, lawmakers, and associations. Because they haven’t seen such solutions yet.” The patents for the development are already secured.

Frank Obrist sees the HyperHybrid as the smarter, more affordable, and globally applicable electrification of vehicles. As a technician, he believes that there is a responsibility to supply people in Siberia, India, Africa, or South America with vehicles. “Elon Musk’s fast charging station in the Congo will take a few more days.” Elon Musk is right that renewable energy is essential, but ultimately, it requires a global solution. That’s why Frank Obrist considers the transport and storage of energy through aMethanol to be the key strategy. Ultimately, this also applies to trucks, ships, and airplanes.

When can one buy the car from Vorarlberg? Currently, they are negotiating with a major licensee, says Frank Obrist. If everything goes well, he plans to start production in 2025. “Of course, as a 45-person company from Vorarlberg, we can’t do it alone. But by showing what we can do, by developing the engine for series production, and by driving the car, it will become public.”

For their groundbreaking developments in the HyperHybrid and E-Methanol production facilities, the Obrist Group is awarded World Green Technology Leader of the Year 2023.