The globally operating German aluminum specialist alimex – precision in aluminum – is setting high environmental standards in the entire production chain of the material.

alimex is what one understands by “German Mittelstand” in the best sense of the word: One of those medium-sized family-owned companies that have particularly high technological know-how, flexibility and quality and thus convince customers worldwide. In the case of alimex, the associated innovative strength is deep in their DNA. The company revolutionized aluminum processing with its cast plate process back in the 1980s and has continued to develop it ever since.

With the requirement for sustainable and environmentally friendly processes, alimex is now in the midst of the next push of innovation.

Protect the environment and resources

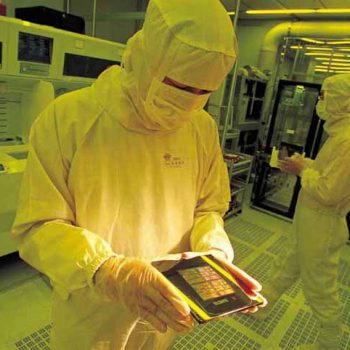

“The example of the aluminum industry shows, like in a magnifying glass, whether the global change to a climate-friendly industry will succeed”, says CEO Dr. Philip Grothe. After all, the industry is one of those most affected by climate and energy policy measures. At the same time, however, it is also the key industry for the innovative technologies of tomorrow. You can experience the importance of aluminum every day at alimex. Because the company supplies high-precision aluminum products for high technologies such as semiconductor production, solar, automotive, mechanical engineering or medical technology. “In this way, the material per se makes a substantial contribution to innovation for sustainable technologies,” says Grothe.

But sustainability must also refer to the production and processing of aluminum as a whole, Philip Grothe is certain. “The topic of sustainability is not an individual project for us, but a comprehensive and permanent process with ever new challenges that we as a company are happy to face. Because it is about protecting the environment and resources in the interests of society and future generations ”.

As a result, alimex has established itself not only as a proven quality supplier for aluminum, but also as one of the providers of the highest environmental standards.

Recyclability speaks for aluminum

In concrete terms, this meant for the family company many years ago to shorten delivery routes and to be on site in the most important markets instead of just delivering there. Locations in the Netherlands, the USA and Asia (Malaysia) were established. At alimex, the importance of the supply chains is also related to its own suppliers. They focus on transparency and purchase aluminum exclusively from Western Europe, a region with very high standards.

High investments have also been made in sustainable production methods, most recently through the construction of a highly efficient annealing hall. Sustainability measures were also implemented throughout the entire operating process, both large and small, by the 160-strong team: from the use of energy-saving LED lamps, the conversion of the vehicle fleet to electric or solar vehicles, the air-heat exchange in the production halls through smart Control up to low-plastic packaging of the aluminum plates, blanks and components. These efforts are audited and certified by an external body, the German Institute for Sustainability and Economics.

Unexpected product innovations

The company also consistently uses a further component of the sustainable use of aluminum – and Grothe sees this as one of the decisive criteria for the material: its recyclability. No cutting or milling residues remain unused. Any scrap is melted down again at alimex and fed into the cycle. “Reusability without loss of quality speaks for aluminum as a material,” says Grothe.

These aspects and the product properties as a whole make aluminum the key material for a number, if not the majority, of all innovations for sustainable technologies. And the flexible medium-sized company alimex has become one of its innovative pioneers.